Structural Health Monitoring (SHM)

Collecting data in real-time allows organizations to make decisions based on the assets’ actual condition, and the implementation of these tools contributes to optimization in terms of integrity, performance, and safety.

By combining state-of-the-art technology and advanced engineering knowledge EQS Global develops monitoring solutions that proactively enhance risk management, performance, and asset availability.

Structural Health Monitoring (SHM) offers the ability to continuously observe the integrity of Civil and Structural Engineering related assets in real-time, with the goal of validating design during construction, enhancing safety and reliability, and reducing maintenance and inspection costs.

Rotating Equipment Health Monitoring

EQS Global condition monitoring solutions enable clients to anticipate future issues by monitoring the asset’s health. With state-of-the-art technology, proprietary monitoring platform, and advanced engineering knowledge it is possible to monitor deviations from normal operational and produces useful insights.

Through connection to data historians and DCS/SCADA, making use of advanced pattern recognition and machine learning algorithms, our predictive analytics solutions enable clients to anticipate and identify future asset failures, helping organizations to adapt maintenance plans, reduce costs, and increase plant availability.

Piping & Pipeline Monitoring

Mechanical Integrity of piping and pipelines it’s an increasingly recognized worldwide challenge, it plays a significant role in demonstrating Fitness-For-Service and the potential life extension.

Real-time or continuous Mechanical Integrity monitoring can complement existing inspection methods and reduce inspection and maintenance costs while increasing reliability and performance levels.

Using monitoring systems and the correct maintenance strategies can result in a significant financial return and the improvement of performance levels.

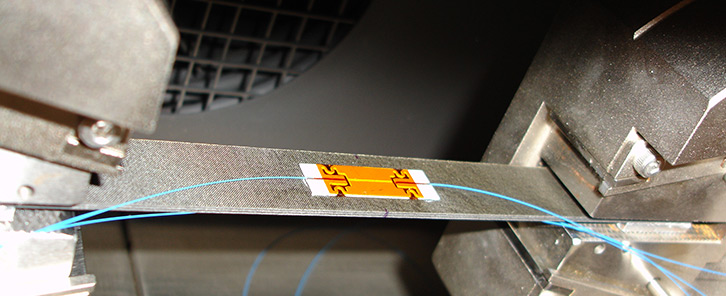

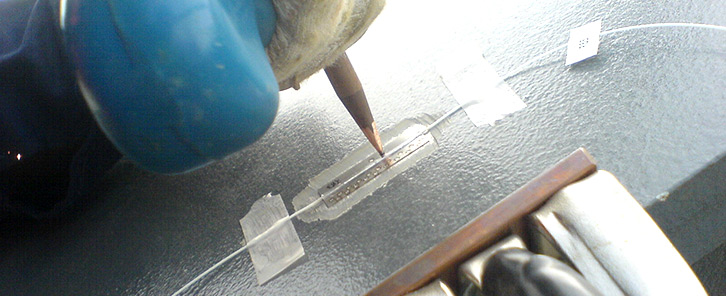

Structural Health Monitoring (SHM) Using Optics & Acoustics

Optical sensing applications have largely increased over the last few years, and it is already widely used in harsh environments involving high radiation, extreme temperatures, pressure, and acceleration.

The intrinsically safe nature of optical sensing and its immunity to electromagnetic interference makes it a powerful option for Power Generation, and Oil, Gas, and Chemicals Industries due to High-voltage, nuclear, and potentially explosive environments.

The small size and weight, and possibility to be embedded in a wide range of materials, turns Optical sensing the right solution for other high demanding industries as aerospace.

Structural Health Monitoring (SHM) For Civil Engineering

Structural Health Monitoring (SHM) offers the ability to continuously observe the integrity of Civil and Structural Engineering related assets in real time, with the goal of validating design during construction, enhancing safety and reliability and reduce maintenance and inspection costs.

Sensors are installed and real-time data is continuously being collected and compared with the baseline to identify structural changes over time. A Web interface displays the information in the form of time-dependent Key Performance Indicators (KPIs) and risk levels. An automated data analysis module allows a continuous detailed integrity evaluation.

SHM FOR CIVIL ENGINEERING PARAMETERS & MAIN GOALS

Acceleration & Vibration

● Structure modal analysis

● Cable force measurements

Displacement & Deformation

● Determining crack opening

● Measure expansion joint movements

● Local deformation Analysis

Temperature & Humidity

● Monitor curing temperatures

● Measure temperature gradients

● Monitoring of humidity conditions

Fluid Pressure

● Measurement of pore water

● Measurement of water level

Strain

● Expansion and contraction of materials

● Static/Dynamic measurements

Tilt & Rotation

● Measure variations of angle

Load & Pressure

● Determine magnitude and direction of stress

● Measure tensile forces in rods and cables

● Bolt torque and applied loads

● Measuring water and hydraulic jack pressures

Corrosion

● Reinforcement corrosion damage severity

● Evaluation of corrosion rate

Do you want to know more? Request a Quote