Asset Integrity Management Consulting

In modern engineering, organizations must consider reliability and integrity across the full lifecycle of critical assets. Reliability thinking must be pushed earlier into the design stage and continuous integrity assessments must be provided to support lifecycle operations.

EQS Global provides detailed diagnostics for integrity assessment, performance improvement and decision-making support.

In addition to the multi-disciplinary in-house engineering team and technology, EQS Global uses the most advanced software for asset management, advanced analysis, and simulation.

- Fitness-for-Service Assessment (FFS)

- Remaining Life Assessment (RLA)

- Engineering Critical Assessment (ECAFFP)

- Failure Analysis

- Risk-based Inspection Programs (RBI)

- Integrity Operating Windows (IOW) Inspection Programs

- Management of Change (MoC)

- Hydrogen Attack (HTHA)

- Corrosion Under Insulation & Fireproofing (CUICUF)

Fitness-for-Service Assessment (FFS)

While aging equipment continues to operate, it’s important to ensure the safety of plant personnel, avoid production losses and minimize environmental impact. At the same time, it’s crucial to optimize production and operations practices, in order to enhance competitiveness and economic performance.

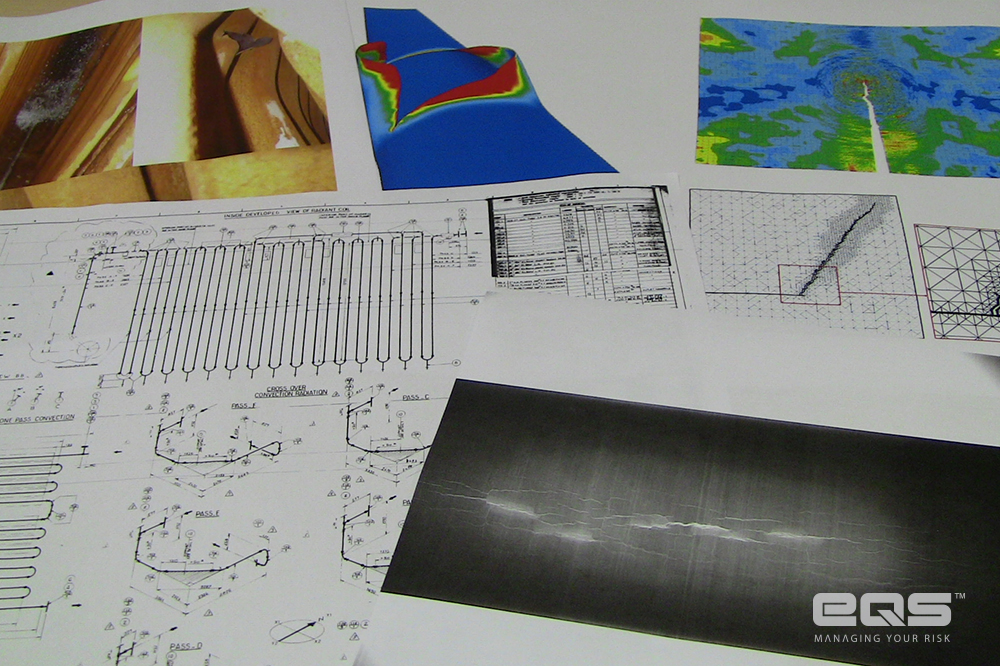

EQS Global performs Level 3 complex engineering evaluations using Fitness-For-Service methodologies, in accordance with API 579-1/ASME FFS-1, or other client specifications, to demonstrate the structural integrity of an in-service component that may contain a flaw or damage or that may be operating under specific conditions that could produce a failure.

In addition to the multi-disciplinary in-house integrity and design engineering team, EQS Global uses the most advanced analysis and simulation tools to deliver reliable results and superior value to the decision-making process.

Remaining Life Assessment (RLA)

Evaluating Asset remaining life requires in-depth knowledge of the degradation mechanisms and their evolution, considering the operating conditions to which the equipment is subjected.

EQS Global performs RLA assessments in the most complex markets. In addition to the multi-disciplinary in-house team, EQS Global uses advanced analysis and simulation tools to deliver reliable results and superior value to the decision-making process.

Engineering Critical Assessment (ECAFFP)

EQS Global performs complex engineering analysis using ECA methodologies in accordance with BS 7910, or other client specifications, to identify the limiting conditions for failure or the limiting design conditions. It can be applied during the design stage, fabrication, and operation.

Through its knowledge and expertise in dealing with fracture mechanics principles and material testing, EQS Global is able to face sector-specific challenges, such as Engineering Critical Assessments to pipeline girth welds subject to cyclic plastic deformation, according to DNV-RP-F108.

In addition to the multi-disciplinary in-house integrity and design engineering team, and NDT and materials experts, EQS Global uses the most advanced analysis and simulation tools to deliver reliable results and superior value to the decision-making process.

Failure Analysis

The prevention of potential damage to an asset is critical for safe and reliable operations in any industry. When failures do occur, an accurate definition of the root cause is an absolute prerequisite to the prevention of future failure events.

EQS Global multi-disciplinary team of engineers has unparalleled expertise in fracture mechanics, materials, metallurgical investigations, and failure modes and effects analysis.

With this EQS Global provides not only reliable failure analysis but also superior technical advisory to reduce component failure risk and static equipment, machinery, and rotating equipment downtime

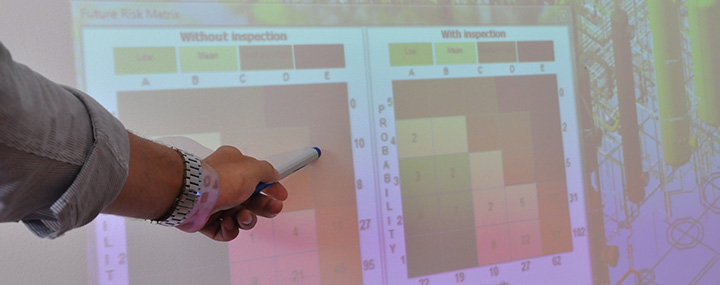

Risk-based Inspection Programs (RBI)

Oil & Gas and Petrochemical industries are constantly facing great pressure to reduce risks and improve safety and environment-related issues. Owners still make a constant effort aiming to reduce production costs and optimize maintenance activities.

EQS Global team has significant experience developing risk-based inspection (RBI) programs on fixed equipment and piping in the hydrocarbon and chemical process industries, and offshore pressure systems. These programs are based on API RP 580, API RP 581, DNV-RP-G101, and the best engineering practices and client specifications. The programs are complemented by the implementation of software and technology.

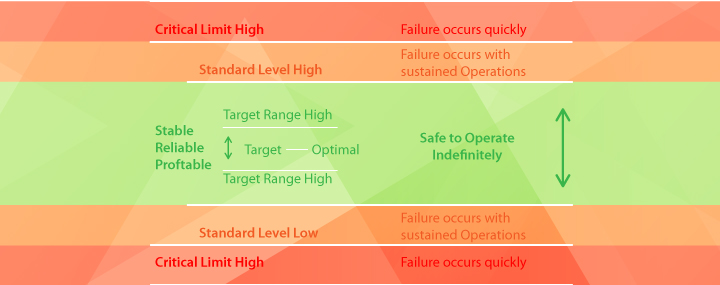

Integrity Operating Windows (IOW) Inspection Programs

All process units have established a set of operating ranges and limits for key process variables. Integrity Operating Windows (IOW) is shown as a specific subset of these operating limits or operating envelopes, related to the maintenance of the process equipment integrity and reliability.

EQS Global provides specialized technical advisory services based on API RP 584 and API RP 571, which identifies some of the major equipment damage that must be prevented – localized corrosion, mechanical damage and metallurgical, corrosion high temperature, among others.

EQS Global understands the importance of maintaining its clients’ assets to operate efficiently and in accordance with the main international standards. In this sense, it develops, in close collaboration with its clients, integrated plans for asset integrity control and monitoring, in order to maintain its integrity throughout the life cycle.

Management of Change (MoC)

Incidents caused by changes in physical assets and process conditions continue happening. Where changes are introduced that could have an impact on asset management activities, the organization shall have a proper Management of Change (MOC) process to assess the associated risks before they are implemented.

An effective MOC process is crucial to anticipate integrity problems and prepare maintenance, inspection, and monitoring plans to address possible design or process conditions changes.

With multi-disciplinary in-house integrity and design engineering team, and using advanced simulation tools, EQS Global can revise processes, update procedures, and anticipate the impact of complex changes in asset integrity management systems.

Hydrogen Attack (HTHA)

High-Temperature Hydrogen Attack (HTHA) is an insidious condition that can occur in process equipment exposed to hydrogen at elevated temperatures (at least 400F or 204C), under dry conditions, when hydrogen disassociates into nascent (atomic) hydrogen, which is then driven into the steel by the temperature and pressure of the environment. The atomic hydrogen then reacts with unstable carbides in steel to form methane gas, which accumulates in the microstructural grain boundaries, eventually leading to cracking. This is often hazardous as the equipment usually contains hydrocarbons at high pressures and temperatures.

EQS Global engineering and advanced NDT team use their experience, knowledge, software, and state-of-the-art technology to detect and evaluate HTHA.

Our services include:

– Hydrogen Advanced Ultrasonic Testing

– Metallography & Materials Characterization

– Fitness-For-Service Assessments (FFS)

Corrosion Under Insulation & Fireproofing (CUICUF)

Corrosion Under Insulation and Fireproofing (CUI/CUF) needs to be addressed with a specific strategy and effective inspection methods. EQS Global has significant experience and in-house technology to study CUI and CUF in the most critical situations.

Our services include:

– Long Range UT (LRUT) / Ultrasonic Guided Waves

– Digital Radiography

– Small Area for Exposure Radiography (SAFERAD)

– Non-Destructive Testing for Concrete

– Thermography

EQS Global is an accredited Third-party inspection Body, Notifed Body (NoBo), and accredited Non-Destructive Testing laboratory, offering a full range of services dedicated to inspection, and the necessary knowledge to support its clients throughout the assets’ lifecycle.

Request a Quotation

Click here to fill the form