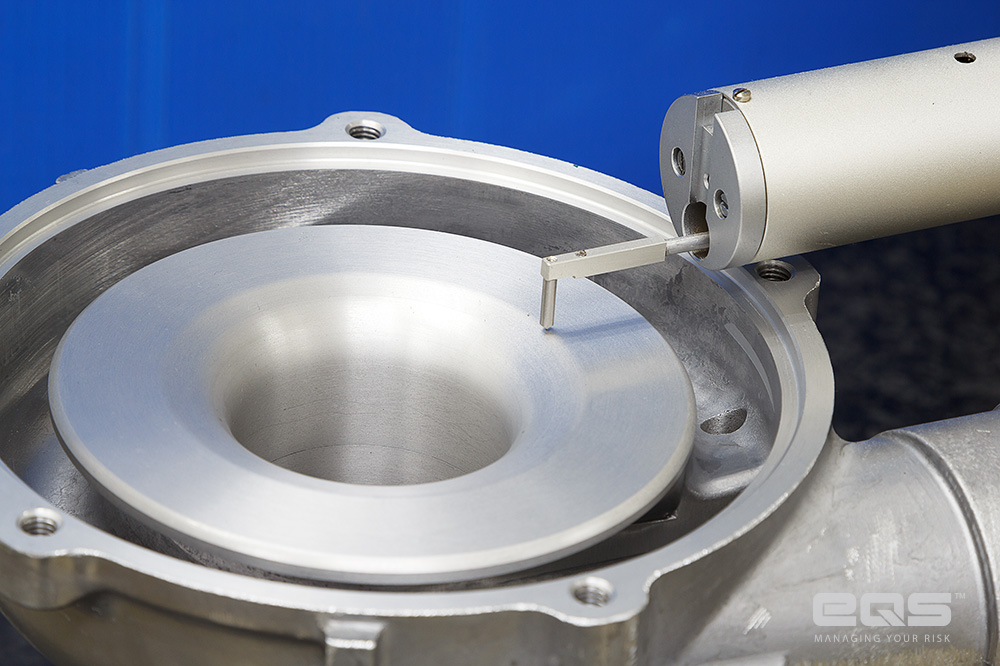

Paint & Coating Testing

Paint and coating are the most critical component in an anticorrosive protection system. Their main function is to provide corrosion protection by adhesion to the substrate. It is then critical that the applied thickness is sufficient to ensure corrosion protection as well as proper adhesion.

The influence of various factors – environmental and others – can contribute to visual and physical changes in paint or coatings.

To ensure that facilities, equipment and systems are in line with the standards and requirements of local and international regulatory agencies, carrying out inspections is essential for the detection of, often invisible, damage.

The applied Tests, by EQS Global, to Painting and Coatings are:

● Bresle Test

● Chloride ion Test for Abrasives

● Chloride Ion Test for Surfaces

● Climate Monitoring

● Cross-cut Test

● Density Cups

● Dry Film Thickness (DTF)

● Dust tape Test

● Glossmeter

● High Voltage Holiday Test

● Low Voltage Holiday Testing

● Pencil Hardness Test;

● Pull-off Test

● Replica Tape Test

● Scrape Test

● Spectrophotometers

● Surface Comparison Test

● Surface Profile

● Surface Roughness

● Ultrasonic Coating Thickness Gage

● X-cut Tape Test

The best partner to guarantee the quality during fabrication

Click here and request a meeting.