Over time, due to material aging, corrosion reduces the original wall thickness of the infrastructures, which may compromise their reliable operation and even cause the collapse of assets.

In addition to representing, in many cases, a risk to the environment, health, and integrity of workers and surrounding populations, this type of situation can cause high economic losses, directly due to unscheduled stops and indirectly due to supply failures.

DISCOVER HOW TO MAXIMIZE THE LIFECYCLE OF THE EQUIPMENT WITHOUT INCREASING RISK AND DOWNTIME

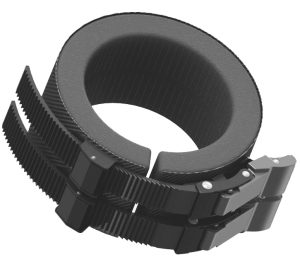

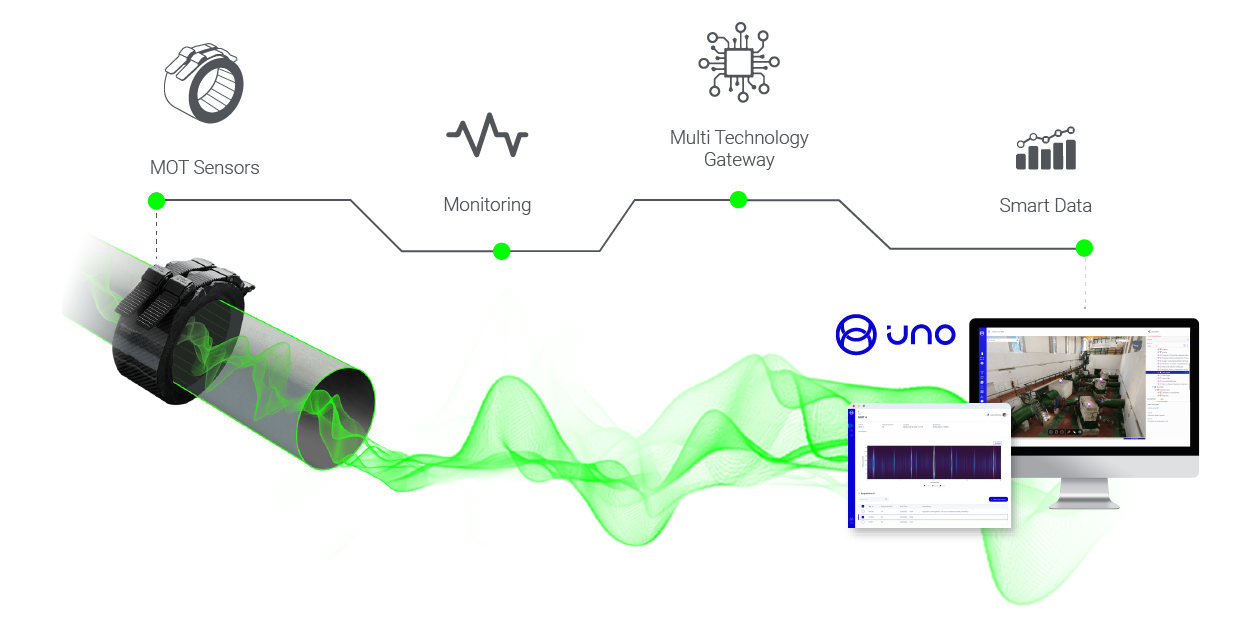

The MOT sensor is an ultrasonic-based screening technology, developed by EQS Global for assessing the integrity of large areas on in-service structures. For instance, in pipelines, from a single excitation point, it is possible to locate internal or external defects, such as corrosion or erosion, at distances of a few tens of meters.

up to 100 meters 360°

In-Service

Moreover, it is possible to evaluate underground, coated, or isolated structures, up to 100 meters of distance, and with a 360º overview, without the need to alter them, providing more comprehensive information about their integrity condition.

MOT is a sensor capable of measuring the thickness of critical assets, considering adverse conditions (ex: high temperature). The system operates continuously, wirelessly, and in real time.

CORE BENEFITS

Know when and where pipelines will fail, without taking the pipeline out of service

Better knowledge of the structural health status of monitored assets

Decreases the risk of high costs of abrupt stops due to failure

Optimization of O&M based on knowledge of the integrity of assets

Investment optimization

Increased production by reducing untimely downtime

Reduction of the installation insurance premium

PIPELINE LEAK DETECTION AND INTEGRITY MONITORINGAPPLICATION IN AN INDUSTRIAL CHEMICAL PLANT

PAIN

Early leak detection in a 4000 meters long ammonia pipeline

INTEGRATED SOLUTION OF TWO TECHNOLOGIES

EQS first installed a distributed measurement system using fiber optics attached to the 4 generatrixes of the pipeline. With this system, we can identify, with a 2 meters resolution, ammonia leakage.

Leak detection is an important part, however, it will not be enough to anticipate the occurrence of a leakage. For this, and through our MOT sensors, a proprietary technology from EQS, it is possible to identify these possible leaks before they occur. MOT technology allows the monitoring of mass loss in-service, and with the integrity evolution reports, it is possible to know when the asset will fail.

4.000 meters ammonia pipeline monitoring with leak detection and integrity monitoring (MOT)

Real-time leakage detection

High-range (thousands of meters) pipeline monitoring

Compatible with different pipeline application

UNO SOFTWAREPREVENTIVE AND PREDICTIVE MANAGEMENT

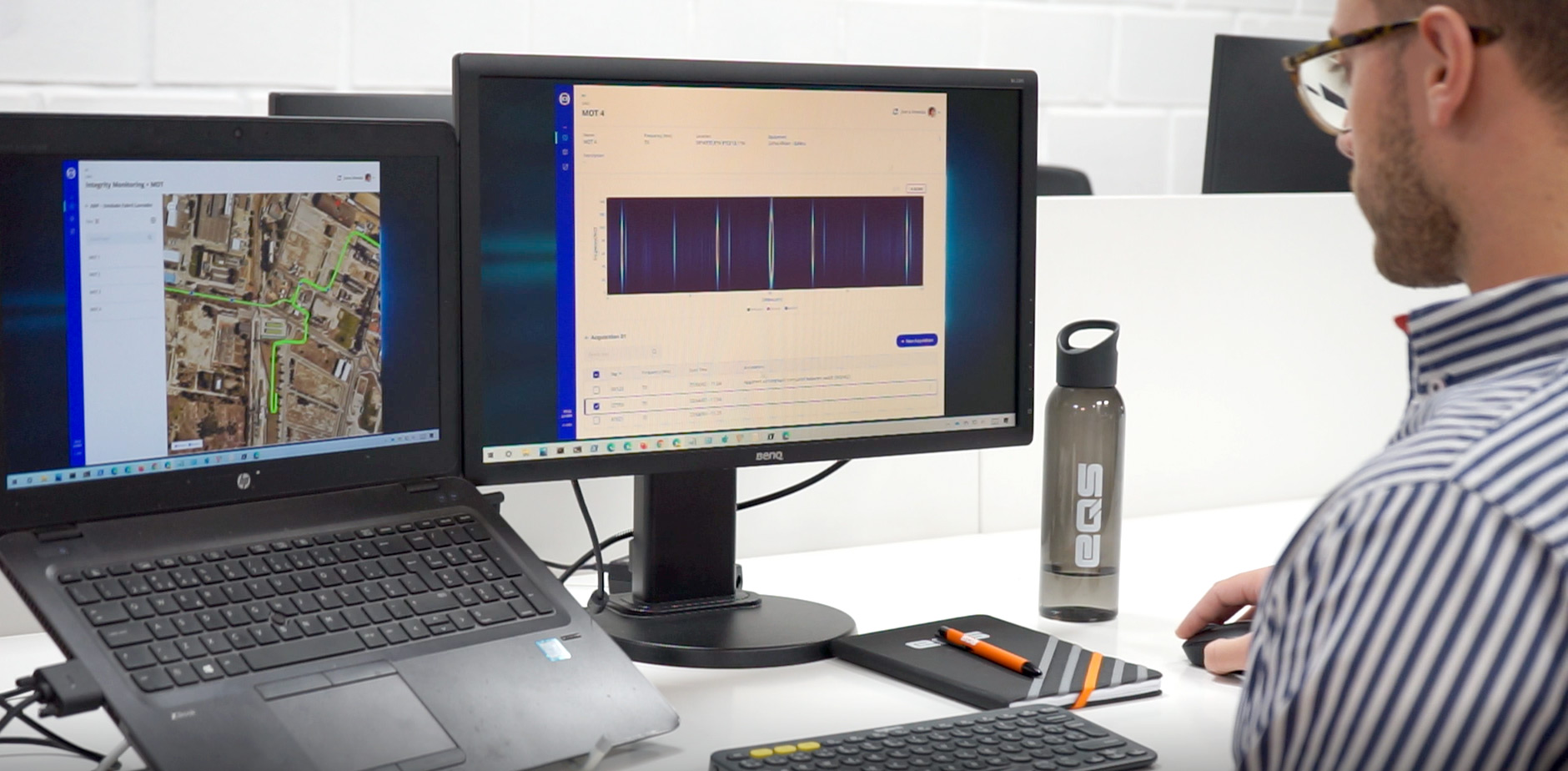

UNO platform predictive algorithms produce real-time insights, promoting preventive and predictive asset management, and the management of the useful life of the asset by inferring the possible consequences on the long-term performance.

EQS Digital’s monitoring and forecasting systems guarantee a holistic and standardized view of all sites and equipment, so that our customers reduce operating costs, optimize investments, and reduce unscheduled downtime.

Ready to start MONITORING your assets?