ULTRASONIC SCREENING

Tanks, pressure vessels, and pipelines are omnipresent infrastructures in the industry, where they are used to store and transport products and raw materials to and from factories and, in many cases, to distribution points and end customers. Over time, due to material aging, corrosion reduces the original wall thickness of the infrastructures, which may compromise their reliable operation and even cause the collapse of assets. In addition to representing, in many cases, a risk to the environment, health, and integrity of workers and surrounding populations, this type of situation can cause high economic losses, directly due to unscheduled stops and indirectly due to supply failures.

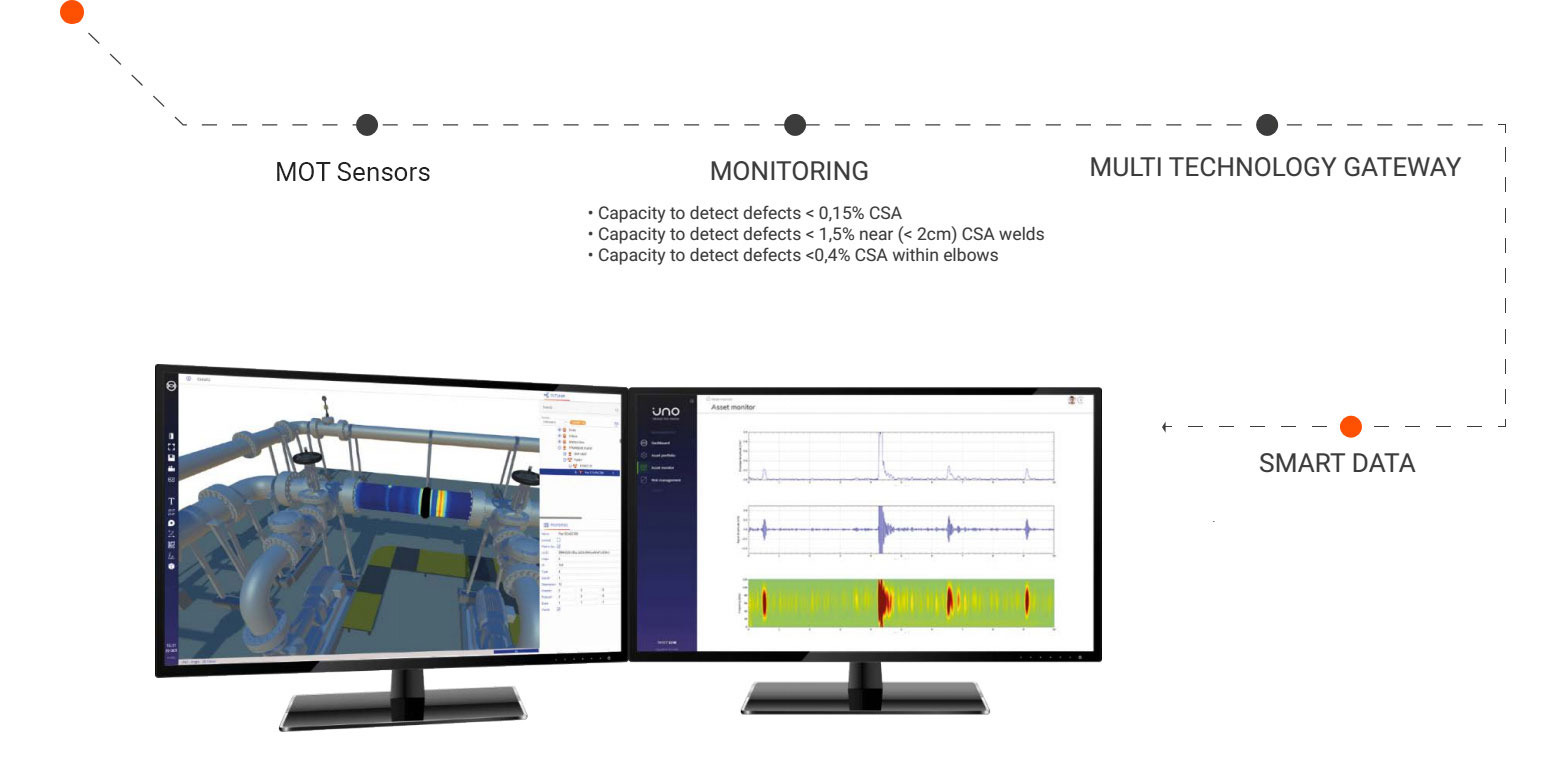

The Magneto-Optical Transducer (MOT) is an ultrasonic-based screening technology, developed by EQS Global for assessing the integrity of large areas on in-service structures. For instance, in pipelines, from a single excitation point, it is possible to locate internal or external defects at distances of a few tens of meters. Moreover, it is possible to evaluate underground and coated or isolated structures without the need to alter them, providing more comprehensive information about their integrity condition.

WHY MONITORINGKnow when and where pipelines will fail, without taking the equipment out of service

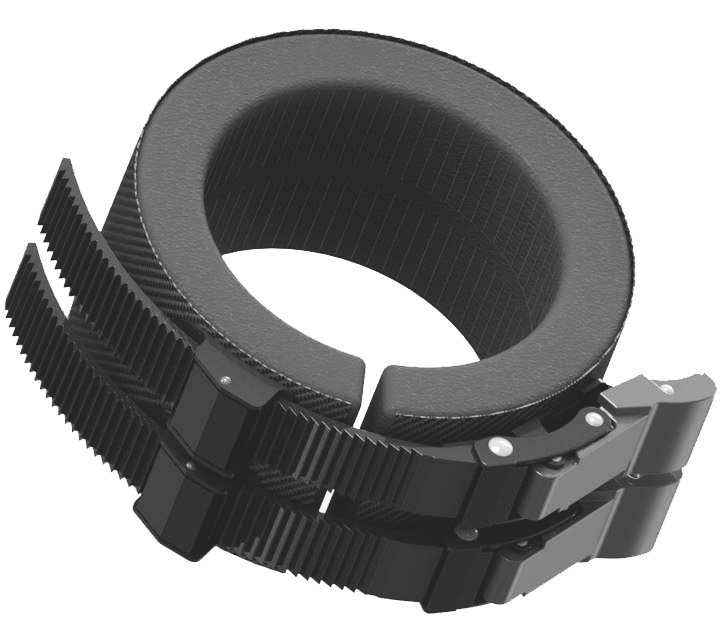

EQS developed a patented Magneto-Optical Transducer (MOT) Ultrasonic that performs a large area screening with 360º mass loss detecting capabilities on pipelines, pressure vessels, and other critical assets. The EQS Digital MOT technology combines magnetostrictive wave generation with quasi-distributed fiber optic-based passive wave detection, to ensure up to 100 meters in length and 360º analysis.

• Better knowledge of the structural health status of monitored assets;

• Decreases the risk of high costs of abrupt stops due to failure;

• Optimization of O&M based on knowledge of the integrity of assets;

• Investment optimization

• Increased production by reducing untimely downtime

• Reduction of the installation insurance premium

![]() REDUCE UP TO 25%

REDUCE UP TO 25%

DOWNTIME

![]() REDUCE UP TO 15%

REDUCE UP TO 15%

IN OPERATING EXPENSES

WHY MOT SYSTEMTechnology for critical assets structural monitoring

MOT is a sensor capable of measuring the thickness of critical assets, considering adverse conditions (ex: high temperature).

The system will operate continuously, wirelessly, and in real-time.

The transducer will be produced by a hybrid process of Additive Manufacturing multi-material laser that will allow the customization of the product.

• A single measurement point covers a large area

• Quasi-Distributed measurement

• Increased range

• Improved resolution (0.15% cross-section area loss) and data reliability

• Temperature mapping

• Increased location accuracy

• Angular location

MOT - DOWNSTREAM, MIDSTREAM & UPSTREAM SUPPORTS

- Cost-effective solutions from 2″ up to 48″ (other sizes upon request)

- Transducers with a frequency range from 30 KHz – 150 KHz for aboveground pipelines

- Transducers with a frequency range from 5 KHz – 30 KHz for buried pipelines

- 360° magnetostrictive patch for increased emission performance together with quasi-distributed fibre optic detection for increased evaluated range (about 2x)

- On-line or off-line monitoring with permanent installed sensors

- Easy installation sensor reduced inspection time and low depence on technician skills.

It also integrates sensor Big Data analysis software for predictive analytics, minimizing risk and improving customer decision making.

MOT compared with others technologies

| Piezo-electric | Magnetostrictive | MOT | |

| Evaluated length | . | . | . |

| Angular detection | (a) | no | (b) |

| High temperature | (c) | (d) | (d) |

(a) Modal Analysis / Focus

(a) Passive Fiber Optic Angular Detection/ Modal Analysis

(a) Up to 350°

(a) Up to 600°