With a multidisciplinary R&D and Innovation team, EQS provides expert consulting services and digital solutions tailored to the industry, to help clients maximize production, optimize asset performance, improve risk management and accelerate digital transformation.

EQS has been intensively testing existing technologies to obtain a clear vision of each technology’s pros and cons. When improvements are needed, EQS has the full capacity to develop the technology in-house offering the client a comfortable turnkey solution.

MONITORING SOLUTIONS

Sensor Installation and Integration

Sometimes the sensors/control systems that exist in customers do not provide data adjusted to the needs of the digitization process, creating the necessity to replace them.

Choosing the suitable sensors and their location in the process is fundamental and must be defined by a team that gathers all the technical skills.

Technologies:

- Corrosion Monitoring

- Multi-Technology Gateway

- Embedded Sensors

COMMUNICATION

EQS has been intensively testing existing technologies to obtain a clear vision of each technology’s pros and cons. When improvements are needed EQS can make them.

The use of wireless communication is one of the possible ways to interconnect new systems in existing installations, where the opening of ditches for the passage of cables is not possible or difficult. However, the existence of electromagnetic interferences, big obstacles, distance, and other constraints inhibits the use of some types of wireless communication.

Through wireless communication solutions, it is possible to implement a monitoring network with a lower investment compared to the conventional cable alternative.

ARTIFICIAL INTELLIGENCE

Converting data into useful information

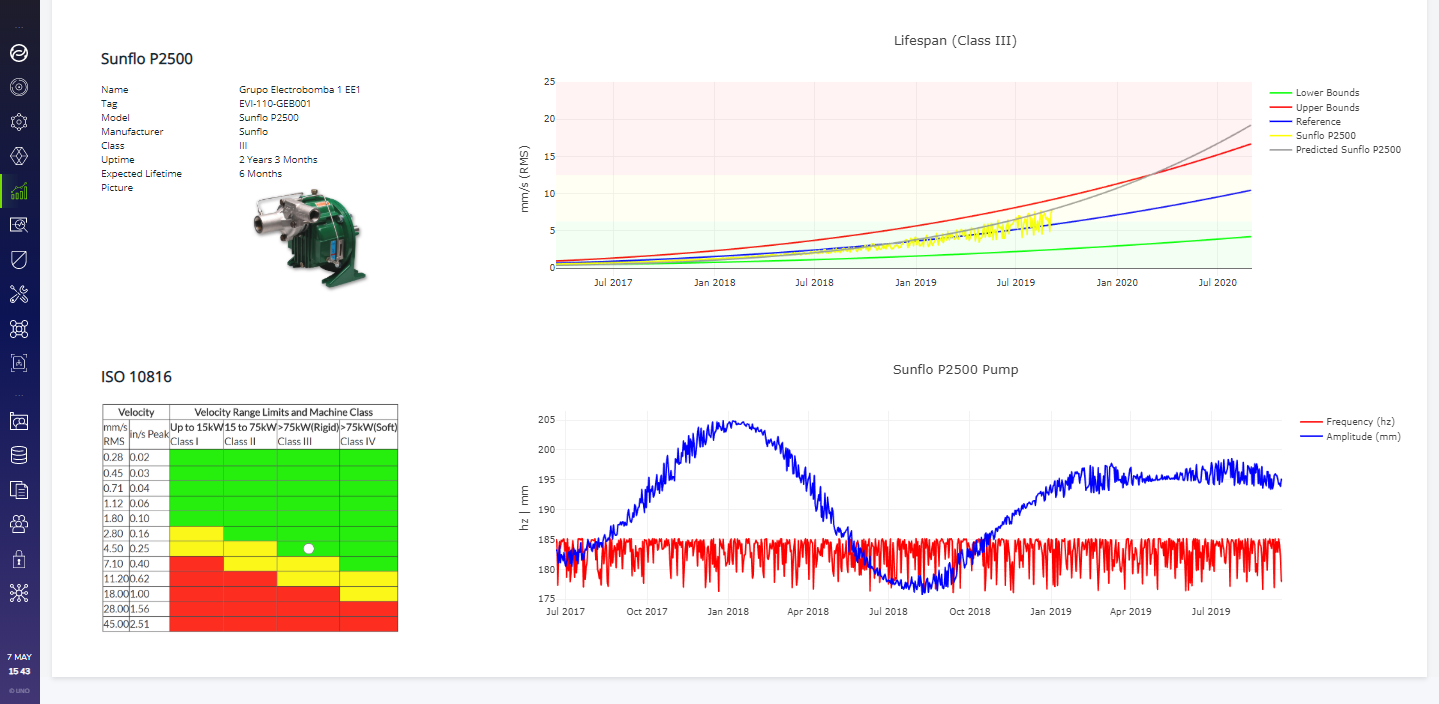

The combination of Artificial Intelligence and big data allows understanding better the health of assets, operations, and/or business. It also gives us the benefit of predicting upcoming trends or risks, avoiding unscheduled downtime.

Prediction

The shift to a predictive modus operandi allows for substantial gains in operating costs and unscheduled downtime reduction, and production maximizing.

Pattern Recognition

Pattern recognition is extremely important for event standardization and root cause analysis.

Key Variables Analysis

EQS develops systems that analyse all variables and contextualize them with many data sources to identify critical variables. By knowing the equipment and process critical variables, users can for example define complex alarms.